Our Bespoke Solutions Turn Unique Rail Weighing Challenges Into Innovative, Practical Results

At Weighwell, we excel at transforming specific challenges into innovative solutions. By combining decades of experience with advanced design tools like SOLIDWORKS, we engineer custom products tailored to your exact operational needs. This approach helps our clients meet their goals with confidence, precision and efficiency.

SOLIDWORKS: Innovation at Our Core

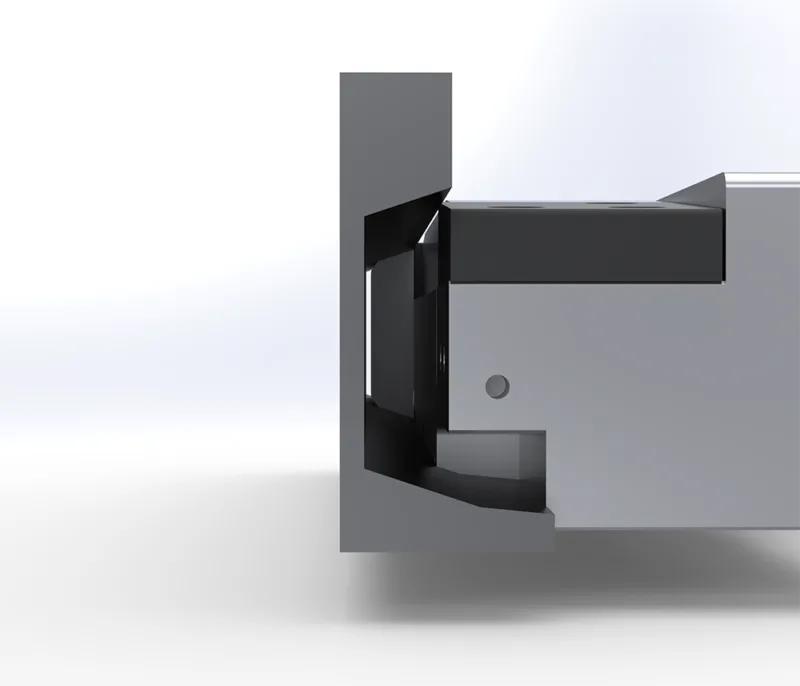

Using SOLIDWORKS, we can create detailed 3D models, simulate real-world conditions, and accelerate product development. This technology enables us to:

- Turn concepts into working solutions more quickly.

- Refine and test designs before production to reduce errors.

- Deliver robust, high-performance products customised to your specifications.

Thanks to this “quality first” approach, every custom project receives focused attention throughout the design process—resulting in practical, reliable and forward-thinking solutions.

Turning Challenges Into Solutions

We take pride in adapting to each customer’s unique requirements. Below are a few examples of how we’ve delivered bespoke solutions:

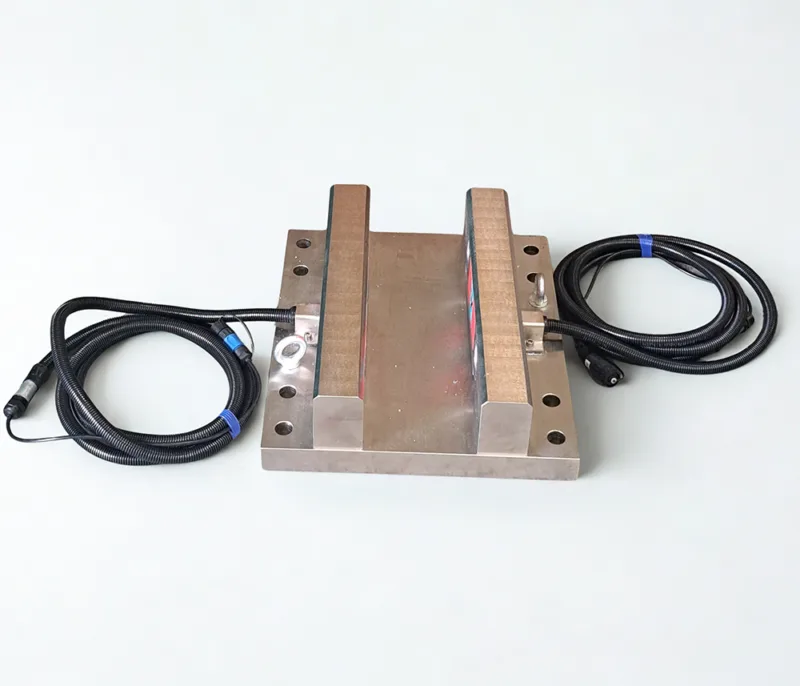

Bespoke Modifications for Smaller Rail Profiles

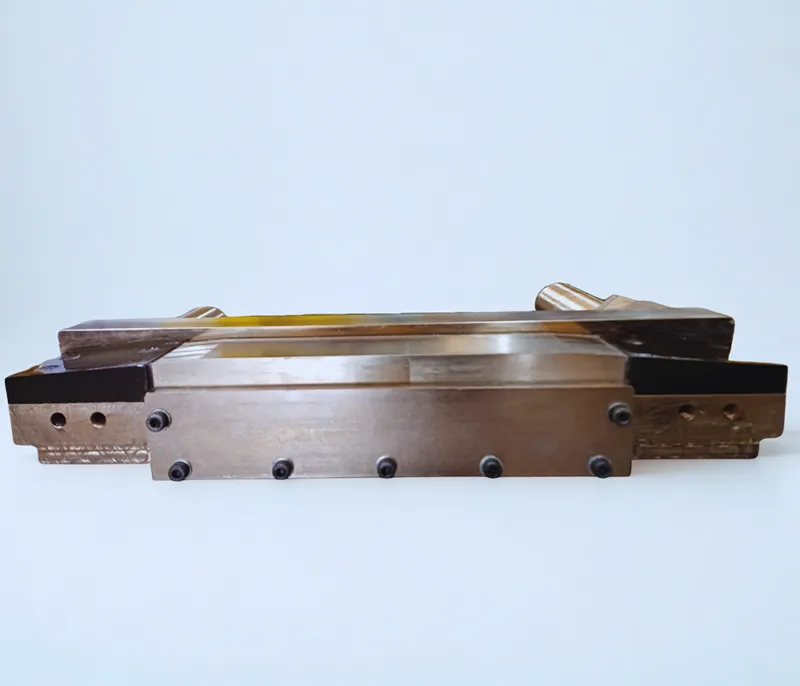

Challenge: All rail vehicle wheels have a flange that keeps the train securely on the track. The PTW system lifts the wheel tyre while keeping the flange within the rail head. However one customer had a very small rail profile, which meant our standard PTW system would either lift the wheel tyre too high or lack the sufficient clearance needed below the rail.

Our weighing solution: Changing the rail profile or weighing location wasn’t feasible, so we redesigned the PTW assembly by:

- Developed bespoke low-profile loadcells.

- Machined the PTW assembly to sit lower.

- Manufactured custom rail keys.

The modifications resulted in the PTW assembly having a lower overall height, which allowed us to maintain the necessary clearance between the top of the rail head and the PTW assembly. As a result, the customer was able to keep their existing rail profile and weighing location, without compromising on performance or accuracy.

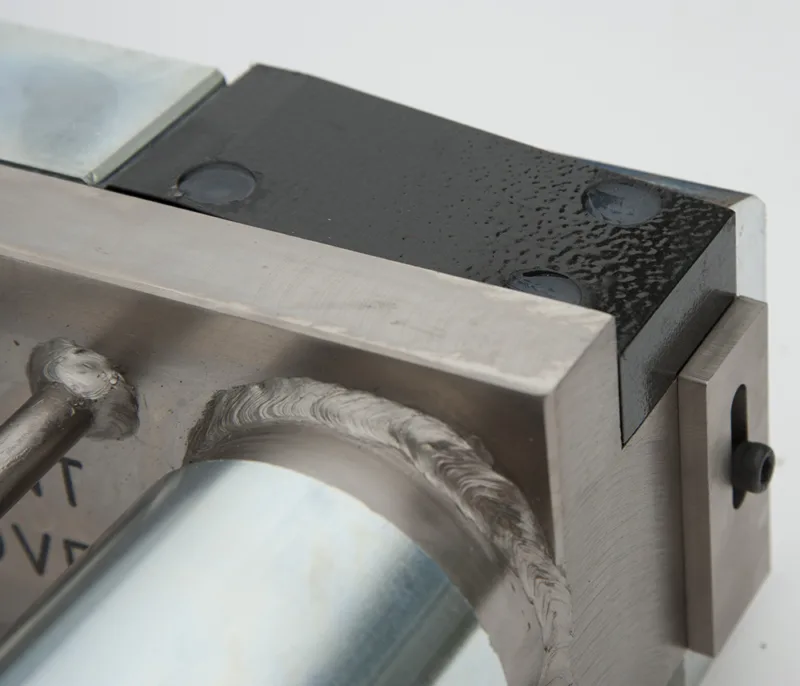

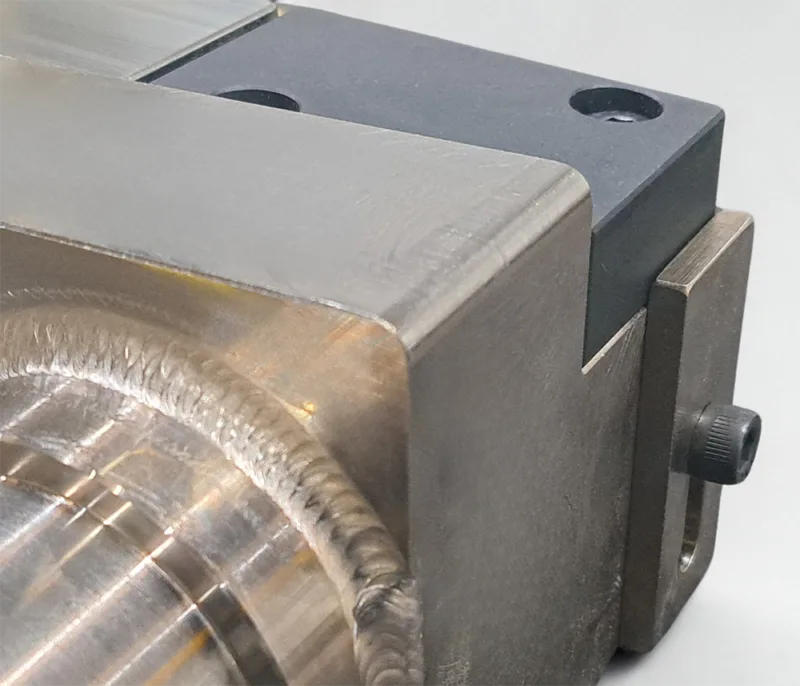

Rounding the Chamfered Edge to Prevent Tyre Damage

Challenge: A client expressed concern that the PTW’s chamfered edge might damage the pneumatic tyres on their mule/shunter during use. They needed a modification to reduce the risk of tyre damage, while maintaining the system’s functionality.

Our weighing solution: We addressed this by rounding off the chamfered edge, removing the risk of tyre punctures. This design improvement was then implemented into our standard manufacturing process. Now, all future PTW systems benefit from this enhanced safety feature, ensuring lasting protection for clients’ shunting equipment.

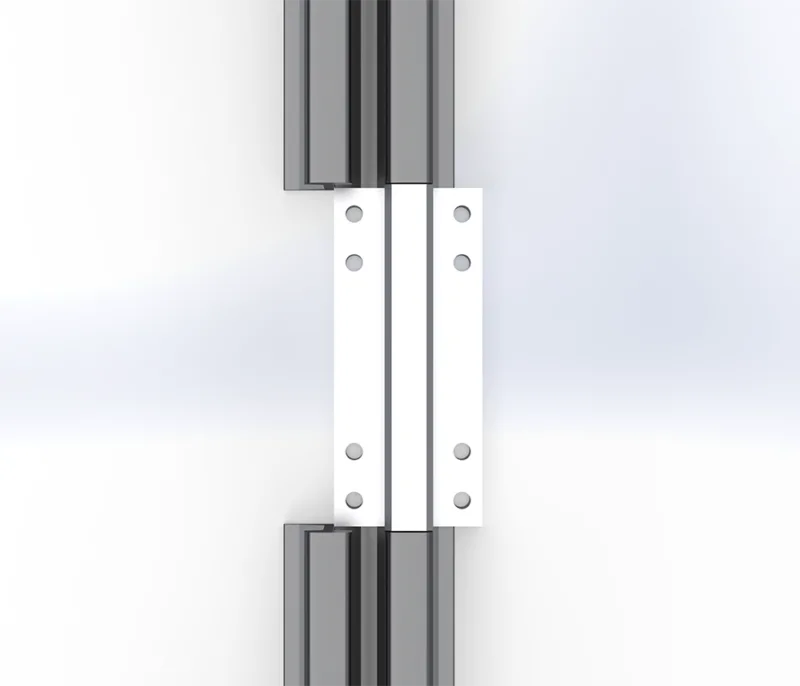

Custom Trackcell™ Design for Multiple Track Gauges

Challenge: One customer needed a TrackCell™ system that could support multiple track gauges. Our standard base plates couldn’t accommodate this arrangement. The distance between two of the track gauges made our standard base plates unworkable and so a bespoke design was required.

Our weighing solution: We designed a single base plate that accommodated two loadcells (rather than one), this allowed us to support the multiple track gauges without affecting the weighing capacity or loadcell performance. This bespoke design met the customer’s exact specifications.

Why Choose Weighwell for Bespoke Solutions?

// Custom Solutions, Built for You

Delivering Bespoke Solutions

By understanding your operational challenges and applying advanced design expertise, we deliver bespoke solutions that support your long-term success. Whether you’re project involves unique specifications or a complex site layout we’re here to help.