The Preferred Choice for High-Accuracy Corner Weighing

Fast Setup, Wireless Connectivity & Reliable Performance

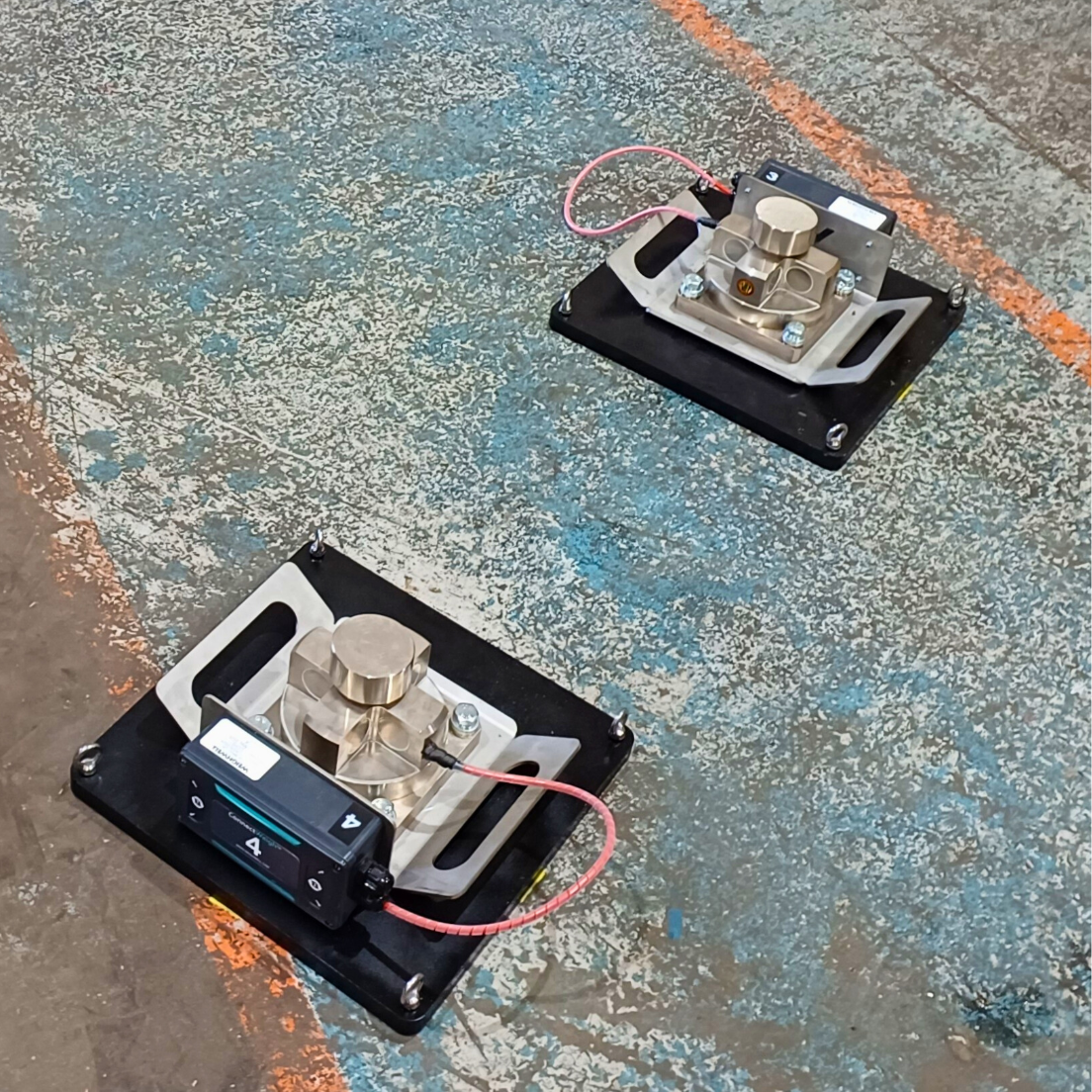

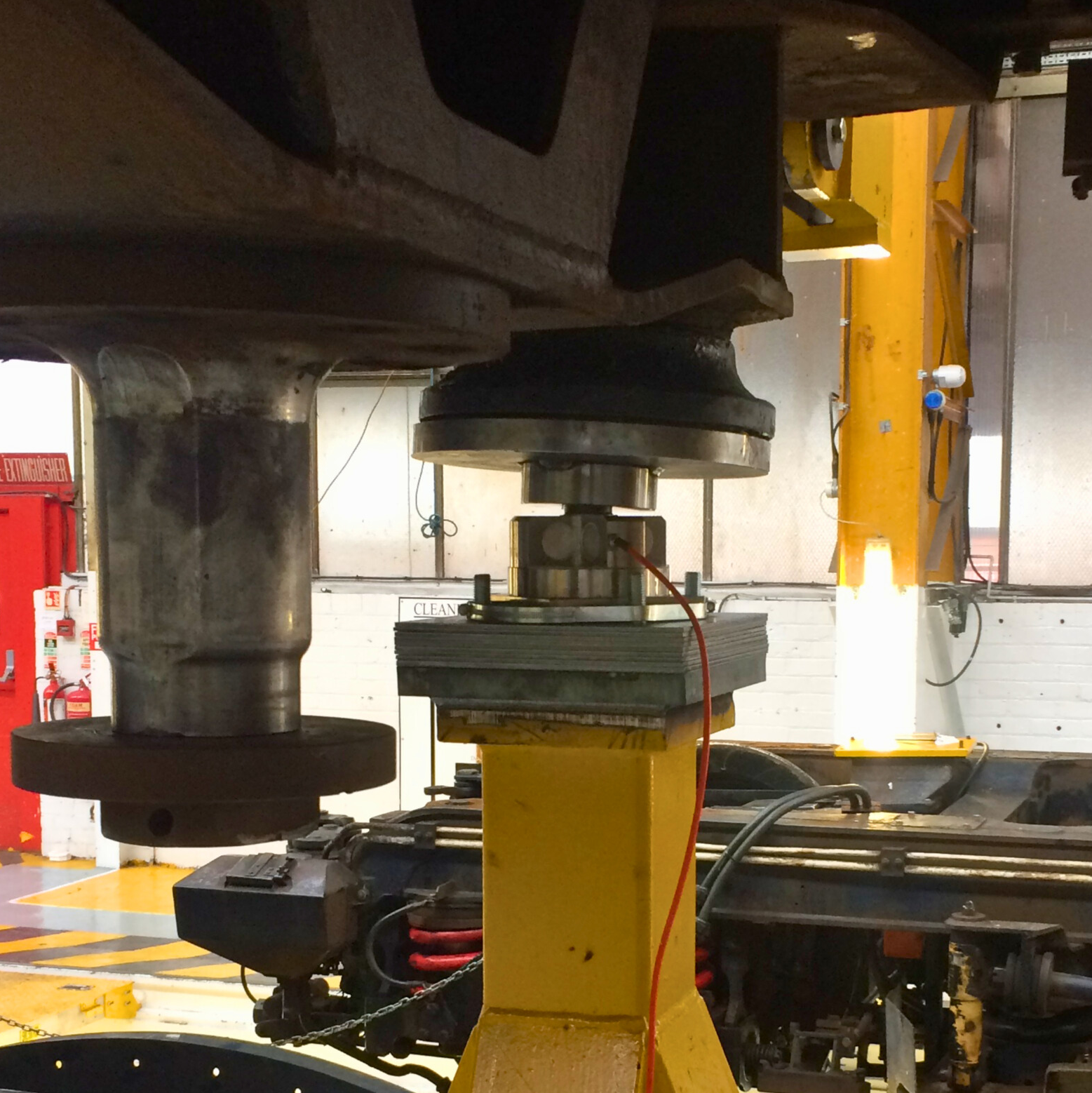

The Corner Weighing System, also known as the CrossCell System, is engineered for precise corner-specific measurements. It ensures accurate weight distribution during key stages of rail vehicle manufacturing and component assembly.

With a setup time of just minutes, the system can be positioned quickly at predefined measurement points. This makes it ideal for weighing railcars, trams, and rail vehicle components such as generator sets, roofs and carbody shells. Moreover, its flexibility extends to industrial weighing needs, including silos, hoppers and storage tanks.

Whether you’re installing the CrossCell system into a new setup or retrofitting it into an existing structure, the load cells can be mounted on lifting jacks and support posts or used directly from floor level. Custom chassis and top plates ensure the load cells are aligned and matched to your lifting points, providing a safer and more accurate weighing process.

Key Features of Our Corner Weighing System

Corner Accuracy

The system delivers reliable corner-by-corner weight data for railcars and vehicle components. This allows engineers to detect imbalances early and make precise adjustments to improve weight distribution.

Purpose Built

Customisable top plates and chassis options allow the CrossCell System to fit your exact setup. This reduces the risk of damage and misalignment while improving safety throughout lifting and measurement.

Loadcell Technology

CrossCell loadcells are traceable to both NTEP and OIML standards. Built to withstand bi-directional forces, they deliver precise, consistent measurements regardless of load direction or placement.

Versatile Application

While purpose-built for the rail industry, the system is equally effective in industries such as agriculture, chemical and mining sectors – wherever durable, accurate and dependable weighing is required.

Technical Specifications

| Accuracy/Repeatability | Achievable accuracy of 0.1%. |

| Dimensions | 104mm high, 150mm wide (excluding accessories). |

| Weighing Capacity | 20,000kg per CrossCell. |

| Power Requirements | Battery or mains power options. |

| Transmission Range | Wireless communication up to 60m in urban environments. |

| Temperature Range | Operates from -20°C to +60°C. |

// Weigh more than just rolling stock

Ready to Elevate Your Weighing Operations?

The CrossCell Corner Weighing System is a dependable, high-precision solution for a variety of weighing tasks—from rail vehicles to individual components. With fast setup, consistent accuracy and rugged construction, it’s a smart choice for rail and industrial weighing needs.