Accurate Static Train Weighing is Essential for Enhancing Rail Safety & Reducing Depot Costs

Our Static Train Weighing Systems

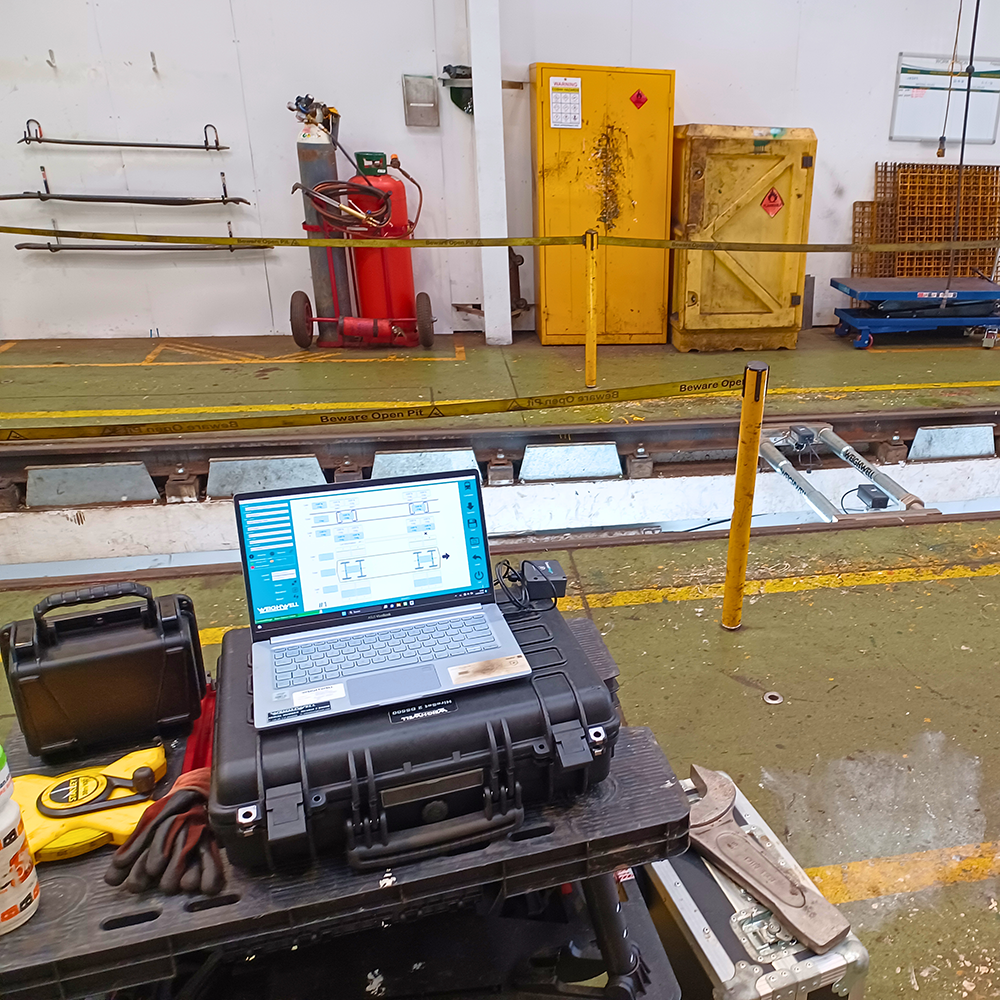

At Weighwell, we understand that static train weighing plays a critical role in both safety and operational efficiency. Since launching our patented Portable Train Weigher (PTW) in 1997, we’ve become a trusted partner for rail depots worldwide.

Our Static Train Weighing Systems provide precise, highly accurate individual wheel weights. As a result, they give engineers a clear picture of the weight distribution across each rail vehicle. This insight is crucial for identifying imbalances promptly and mitigating safety risks.

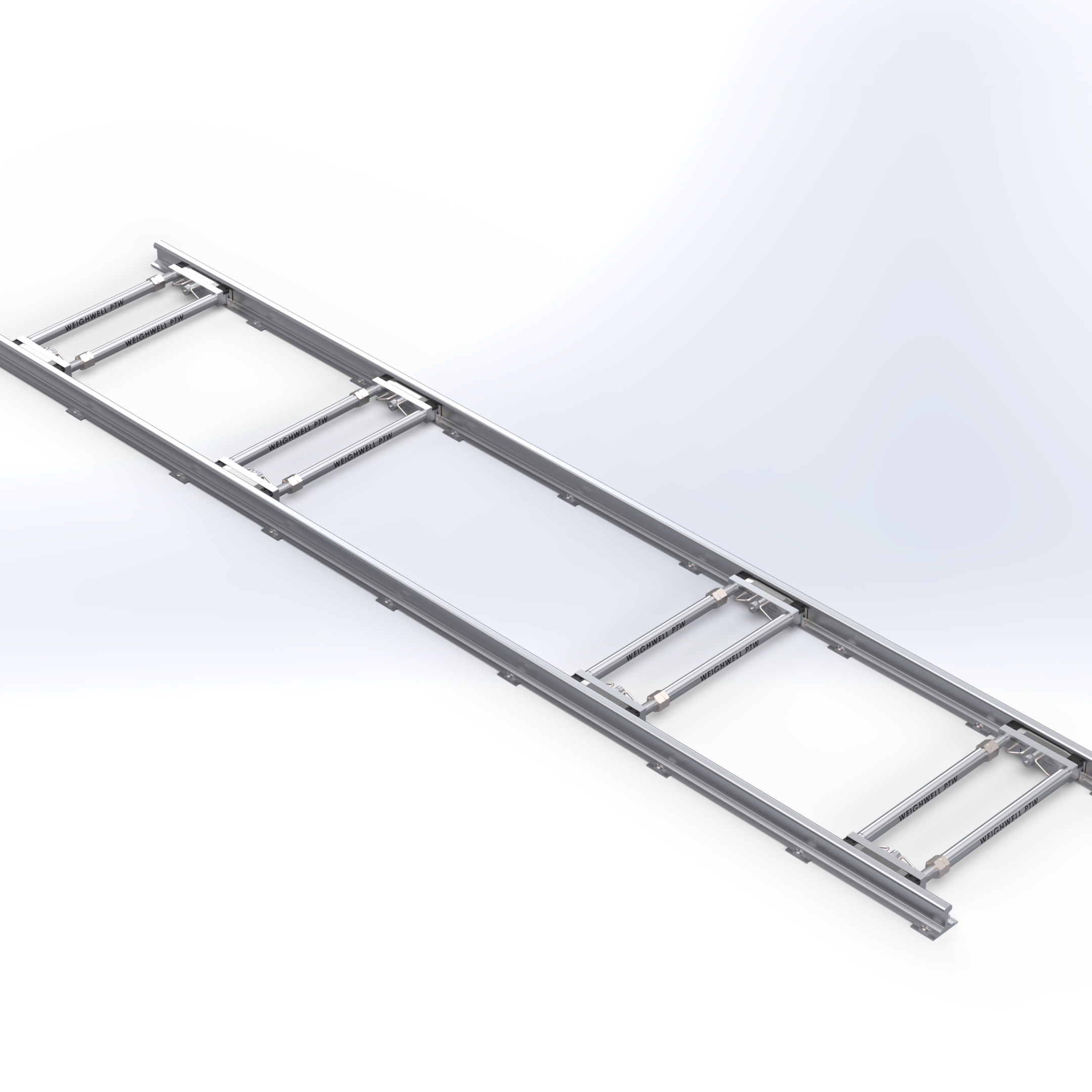

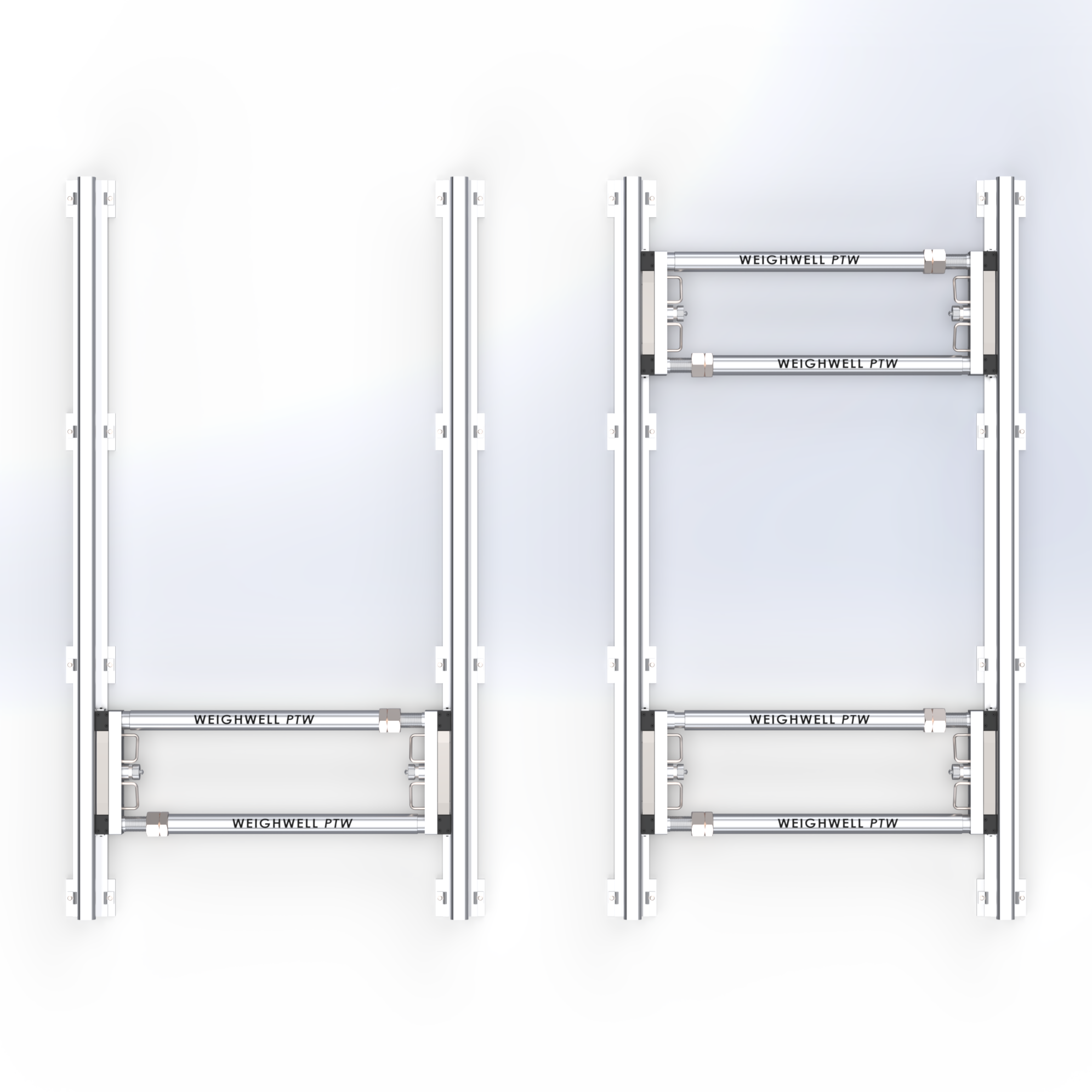

Explicitly designed for train maintenance depots, our PTW systems are available in various configurations, from single to multi-unit setups. Whether you’re weighing axles, bogies (“trucks”) or complete railcars, you can count on our systems for accuracy, reliability and ease of use.

Our Range of Static Train Weighing Systems Includes:

The benefits of additional PTW units include:

Key Features of Our Static Train Weighing Systems

Modular Design

Our range includes axle, bogie, railcar and multi-railcar weighing configurations. You can quickly expand or reconfigure your setup to meet changing operational requirements, such as different vehicle lengths.

Convenient Installation

Each PTW unit is just 500mm in length and can be installed without modifying the track. Designed for quick installation, they fit between rail fastenings and can be installed on ballast, pitted or raised pillar locations.

Flange-Friendly Design

Our patented design features a smoother (flange-friendly) transition. This makes it easier to move rail vehicles onto the weighing system and ensures weight readings are as accurate as possible.

Real-Time Data

Access accurate, real-time weighing data to make immediate, informed decisions. Your rail engineers can make precise adjustments whilst the rail vehicle is stationary on the weighing system.

Why Choose Static Weighing?

Regular static weighing eliminates guesswork during depot maintenance tasks such as levelling by ensuring all adjustments are based on accurate data from the start. This proactive approach minimises dynamic instabilities and provides a better understanding into the rolling stock’s body-to-bogie connections. As a result, rail depots can enhance safety, improve reliability and provide more cost-effective operations.

Precision

Our Static Train Weighing Systems offer unparalleled accuracy by capturing precise individual weights of each wheel, axle and bogie.

Identifying imbalanced wheel loads is vital, as poorly balanced wheels can increase the risk of derailment. Our systems enable rail engineers to take timely corrective actions before minor issues develop into serious safety concerns.

Optimise Depot Maintenance

A wheel imbalance may result from deteriorating wheel wear or faulty suspension components, such as steel springs or bearings.

Static weighing can identify these imbalances, allowing for vehicle repairs and preventive maintenance. By detecting these issues early, rail depots can reduce downtime, prolong rolling stock lifespan and improve overall efficiency.

Testing & Commissioning

Static weighing is invaluable for pre- and post-maintenance testing, ensuring the weight distribution conforms to the relevant safety standards.

The weighing data can help verify that newly assembled and modified rail vehicles are fit for service, reducing the risk of operational issues once they’re in active use.

Technical Specifications

| Accuracy/Repeatability | Achievable accuracy of 0.1% with a PTW unit under each axle. |

| Length | At 500mm, the PTW installs easily between rail fastenings. |

| Capacity | 15,000kg per wheel (heavier capacities are available). |

| Power Requirements | Battery and mains power options. |

| Transmission Range | Wired (15m per axle) and wireless (up to 60m in urban environments). |

| Temperature Range | Built for extreme conditions from -30°C to +70°C. |

// Proven solutions for train maintenance depots

Transform Your Rail Depot Operations Today

With Weighwell’s PTW systems, your maintenance depot benefits from a proven solution that’s portable, accurate and globally trusted. Let us help you improve safety and gain peace of mind with every weighing.